Last updated February 15, 2018 at 1:25 pm

Safer, cheaper batteries with higher density of energy storage move a step closer.

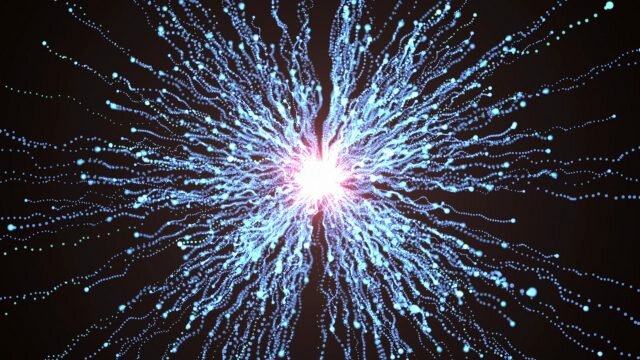

Credit: iStock

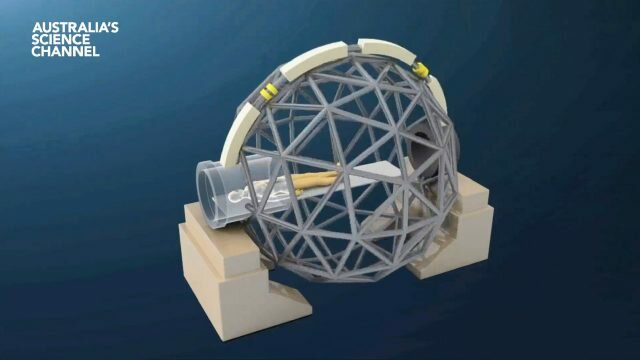

Despite being considered to have a number of advantages over lithium-ion (Li-on) technology, magnesium has been sidelined by a variety of problems, primarily the lack of a suitable cathode or positive electrode – the part of a battery where the magnesium ions enter during discharge of the battery to power an electronic device and then exit during charging.

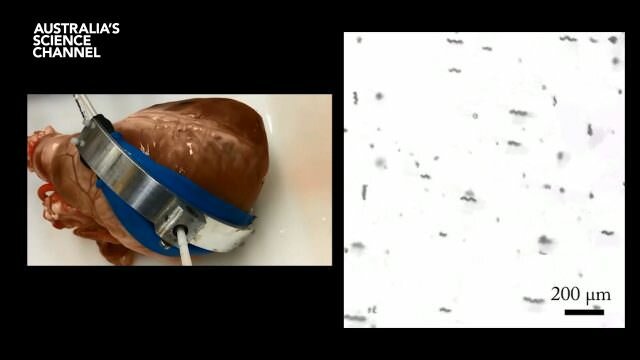

However, a redesigned form of an old lithium-ion cathode material vanadium pentoxide has proved capable of reversibly inserting magnesium ions.

“We’ve essentially reconfigured the atoms to provide a different pathway for magnesium ions to travel along, thereby obtaining a viable cathode material in which they can readily be inserted and extracted during discharging and charging of the battery,” says the leader of the multi-institutional project, Professor Sarbajit Banerjee from Texas A&M University.

This was achieved by limiting the location of the magnesium ions to relatively uncomfortable atomic positions by design, based on the way the vanadium pentoxide is made. This is known as metastability. It helps prevent the magnesium ions from getting trapped within the material and promotes complete harvesting of their charge-storing capacity with negligible degradation of the material after many charge-recharge cycles.

Safety and long-term supply concerns over lithium

Banerjee says the team’s success moves us “one step closer to delivering batteries that promise higher density of energy storage on top of transformative advances in safety, cost and performance” in comparison to their lithium-ion counterparts.

“Currently, lithium-ion technology dominates. However, the safety and long-term supply of lithium remain serious concerns. By contrast, magnesium is much more abundant than lithium, has a higher melting point, forms smooth surfaces when recharging, and has the potential to deliver more than a five-fold increase in energy density if an appropriate cathode can be identified.”

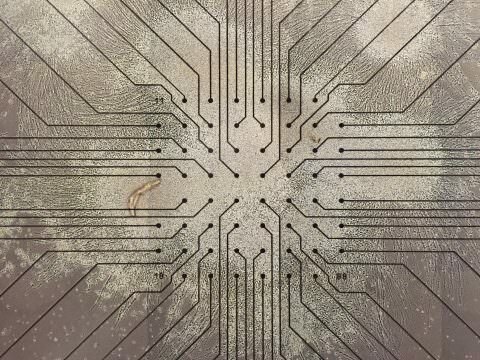

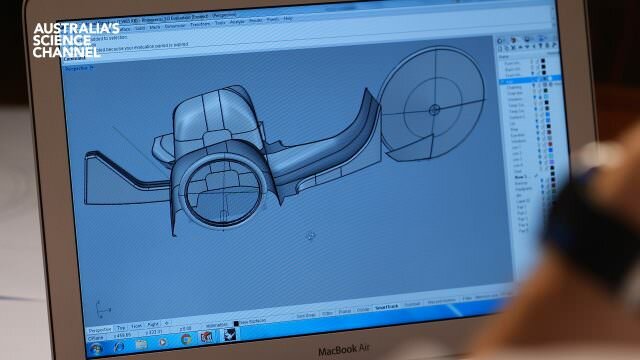

A redesigned metastable phase of vanadium pentoxide (V2O5) shows extraordinary performance as a cathode material for magnesium batteries. The graphic compares the conventional (right) and metastable structures of V2O5. Credit: Justin Andrews, Texas A&M University

Safety is certainly an issue, given recent incidents where Li-ion-powered devices have either caught fire or exploded as a result of the fundamental flammability and reactivity of lithium.

Texas A&M chemistry graduate student Justin Andrews says magnesium-ion technology also is appealing because each magnesium ion gives up two electrons per ion. “This means that, all other considerations aside, if you can store as much magnesium in a material as you can store lithium, you immediately almost double the capacity of the battery.”

However, he admits there is still quite a lot of work to be done. “While this research has provided a great deal of insight, there are still several other fundamental problems to overcome before magnesium batteries become a reality,” he says.

“Nevertheless, this work moves magnesium batteries one step closer to reality — namely, a reality where batteries would be less-expensive, lighter and safer allowing for easier adoption to large-area formats necessary for electric vehicles and to store energy generated by solar and wind sources.”

The paper published in Chem.