Last updated July 11, 2017 at 6:01 pm

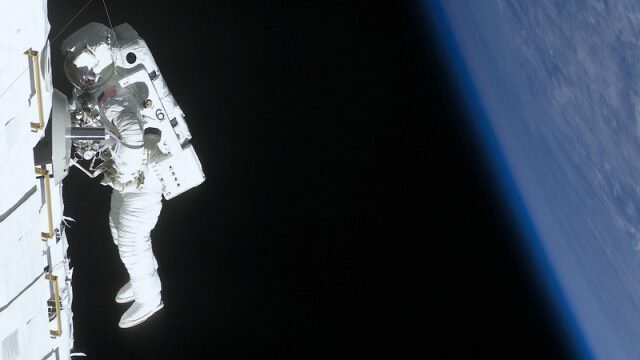

Catch up on the last fortnight’s space exploration news with Go/No Go

SpaceX reuses capsule for the first time

Fresh from reusing a previously launched rocket, SpaceX have successfully reused one of their transport capsules. The Dragon capsule carried nearly 2.7 tonnes of cargo to the ISS.

This was SpaceX’s eleventh mission to supply the ISS, and the same capsule was used previously for the fourth. On that mission the capsule returned to Earth, splashing down in the Pacific Ocean. The capsule was retrieved and refurbished by SpaceX.

The capsule will be loaded with completed experiments and hardware and return to Earth for the second time in July.

Reusability of rockets and capsules is key to SpaceX’s ongoing strategy to reduce the costs of launching cargo and ultimately people into space.

Solar Probe Plus gets a name

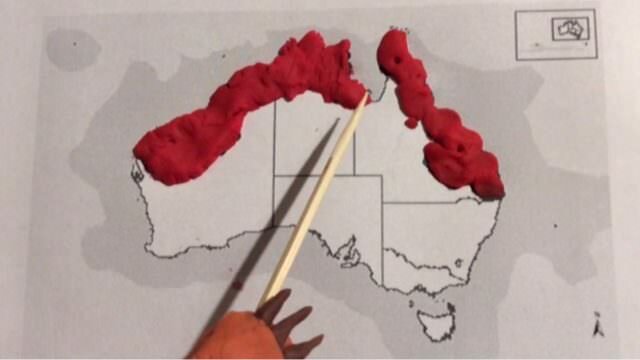

The Solar Probe Plus is no more, welcome the Parker Solar Probe. The probe will be launched in 2018 to get closer to the sun than ever before and investigate the corona and solar winds streaming from the sun.

The probe was named after Eugene Parker who 60 years ago predicted the existence of high speed solar winds – streams of charges particles spewing out of the sun across the solar system.

The Parker probe will scream across the face of the sun at 720,000 km/h, only 6.4 million km above the surface. While that sounds like a long way, if the Earth and Sun were 1 metre apart, Parker would be barely 4 cm away from the sun. At that height it will endure temperatures over 1400 degrees Celsius – making the most of its 11cm thick heat shield.

Inside the corona it will be investigating why that region above the surface of the sun is hotter than the sun itself, why the solar winds accelerate, and also learn more about the radiation itself – knowledge which will be vital as we increasingly send humans into space.

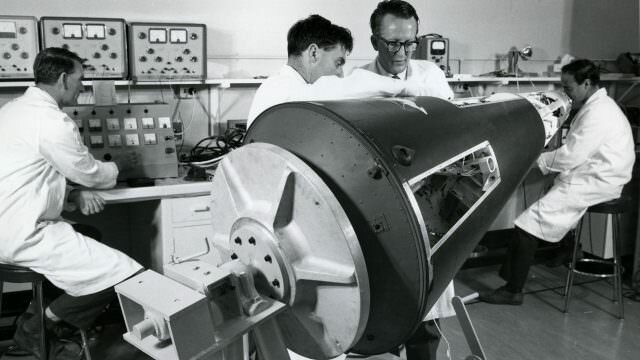

Grab the cake, BEAM turns one

Just over a year ago the Bigelow Expandable Activity Module was inflated on the International Space Station for the first time. A year on, and the fabric balloon-like structure is going strong.

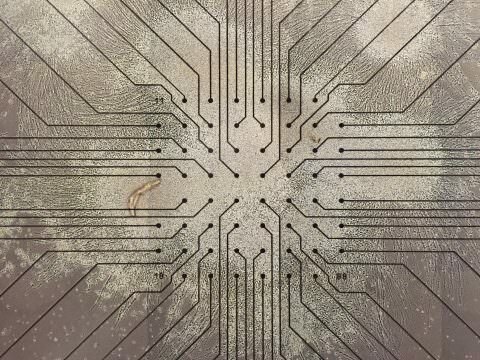

The module is an experimental habitat unit which was transported to the ISS deflated, attached, and then slowly inflated to full size. The past year has seen testing and monitoring to see how well the module has resisted debris impacts, and the results are extremely positive. Sensors inside the unit have been measuring impacts, and have found that BEAM has behaved as expected when struck.

This is the first step to proving the usefulness of inflatable modules on space stations. If BEAM continues to return positive results expect to see more inflatable units used in the future as inflatable units give far more flexibility in module design. At the moment solid units can only be designed to be as large as the rocket flying them to space, but inflatable units can be designed much larger and in different shapes, get launched deflated and only inflated to full size after being positioned in space.

The next year will be crucial for the success of BEAM as focus shifts onto the safety and reliability of the unit. Already data from radiation monitors inside BEAM is showing that radiation levels are comparable to other (solid structure) modules on the ISS. Over the next year astronauts will be 3D printing shields to test around the radiation monitors to find the optimal thickness and effectiveness of onboard-built shielding.

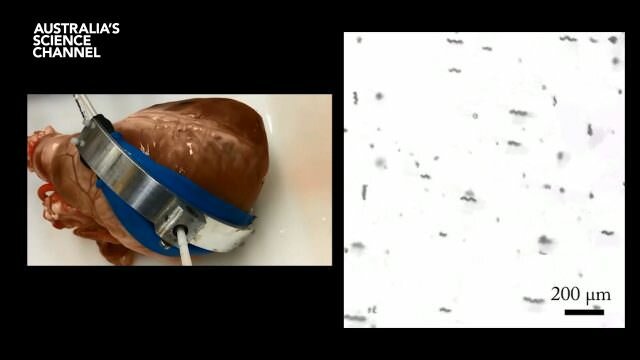

Space medicine is hard

Doctors gathered in Geneva for the Euroanaesthesia congress this week, and one of the topics on the program was medicine in space. It might sound obvious but as we push further out into space and spend longer away from Earth, medical care of crew members will become more and more important.

In the event that something happened off Earth, it’s quite likely the patient would need to be treated by people without formal medical training and without equipment available on Earth. And then there’s the question whether Earth-designed equipment and techniques would even work in space.

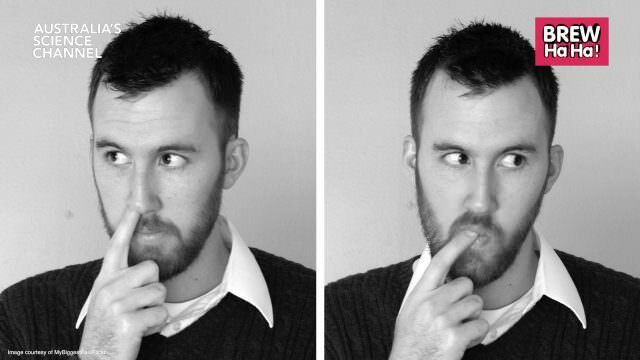

These are the challenges being tackled by experts around the world, and leads to unique approaches such as handstand CPR:

Without gravity an astronaut would struggle to get enough compression into the chest. The handstand allows them to push off the ceiling or nearby equipment to compress the chest. Another technique sees the astronaut wrap their legs around the patient to prevent them flying off during compressions.

Concerns that commercial crew vehicles may not reach safety standards

SpaceX and Boeing, the two companies developing crew vehicles for NASA, may struggle to reach strict safety thresholds stipulated in their contracts, according to reports.

A recent meeting of the Aerospace Safety Advisory Panel was told that the companies are making good progress on the safety of the capsules, however haven’t yet reached the benchmarks dictated to them. Those benchmarks are based on a probability of losing or disabling a crewmember during a mission, and the aim is 1 in 270. The shuttle missions had a loss of crewmember (LOC) probability of 1 in 90 over their lifespan.

Impact from debris and micrometeoroids is one of the key factors in determining the risk faced.

Should either or neither company reach the standard NASA may be forced to issue a waiver. However that doesn’t mean that either company isn’t taking the risk seriously enough. In fact NASA has confirmed that it is happy that both companies are spending the appropriate effort and engineering activity to maximise astronaut safety.

Even Bill Gerstenmaier, NASA associate administrator for human exploration and operations, has warned against getting too hung up about the LOC probability. “It’s not a very good tool for determining absolute risk. That really misleads, sometimes, our overall design decisions.”

Images courtesy of NASA

Follow us on Facebook, Twitter and Instagram to get all the latest science.